First Impremia IS29 in Italy sold to Loretoprint

Vito Ferrone, Managing Director of Loretoprint, tells about the reasons that led to choosing this system: "We are at a new evolutionary cycle of the company, which continues to grow in terms of business and, for this, we felt the need to respond to this development. While the finishing part was recently expanded with new laminating and folding systems, there was a gap in the press that we wanted to fill. Currently, two digital systems are operative in the company for the realization of commercial printings, iGen 4 and Presstek DI, in the 35x50 format, on which we set up our entire production. We realized that the format started to be a limitation for us and we looked for a new solution to respond to increasingly tight delivery times and increasing processing requests."

In this context, the purchase of the Impremia IS29 is introduced, which allows greater flexibility and productivity. As Vito Ferrone explains: "I have been following the evolution of this machine for several years now, a system with features that fully fall within the logic of digital, but are also close to the world of offset. Among the decisive elements, we were convinced of the compact structure of only 5 meters, the 50x70 format that will allow us to be more versatile and, last but not least, the production capacity almost doubled. In fact, only in a second moment, I realized how much speed could represent the real plus of the system for us. The machine reaches a speed of 3,000 sheets per hour in 50x70 format, 6,000 in 35x50 format, and 12,000 an hour in A4 format. Moreover, at twice the speed, it allows to save on yields."

Thanks to the UV LED technology, which the machine is equipped with, the sheet dries instantly after printing and is immediately available at the exit for subsequent processing. "The quality is surprising and comparable to offset," continues Ferrone. - We have experimented at the Komori showroom with prints on which different finishes, as well as finishes were applied that we normally manufacture in Loretoprint and this machine has responded positively to all our tests. In addition, the system will allow us to expand the range of supports, as it can print weights ranging from 60 to 600 g / m² in white, and up to 450 g / sqm in duplex. Thanks to UV LED technology, we can potentially think of printing on plastic too, a challenge for us."

Loretoprint can be defined as "the Swiss pocket knife of the press in Milan", a classic typography for many commercial processes, and has found a versatile machine capable of responding to its needs in the Komori system. "It has the speed and quality of the offset with the manageability of the digital - explains Ferrone. - Inkjet technology is the future of printing, without complexity guarantees maximum stability. I was looking for a versatile system and I think that Impremia IS29 could be the right solution to solve our production problems."

The supplier has counted in the choice too, as Ferrone explains: "In Komori I found a competent team with high professionalism, without forgetting that it is a reference brand for the graphics industry. Komori Italia, supported by the European Headquarters, gave me a sense of reliability and seriousness that convinced me to make this investment. I have come to the conclusion that it is a solid project, guaranteed by a strong brand, and that it will evolve in the future.”

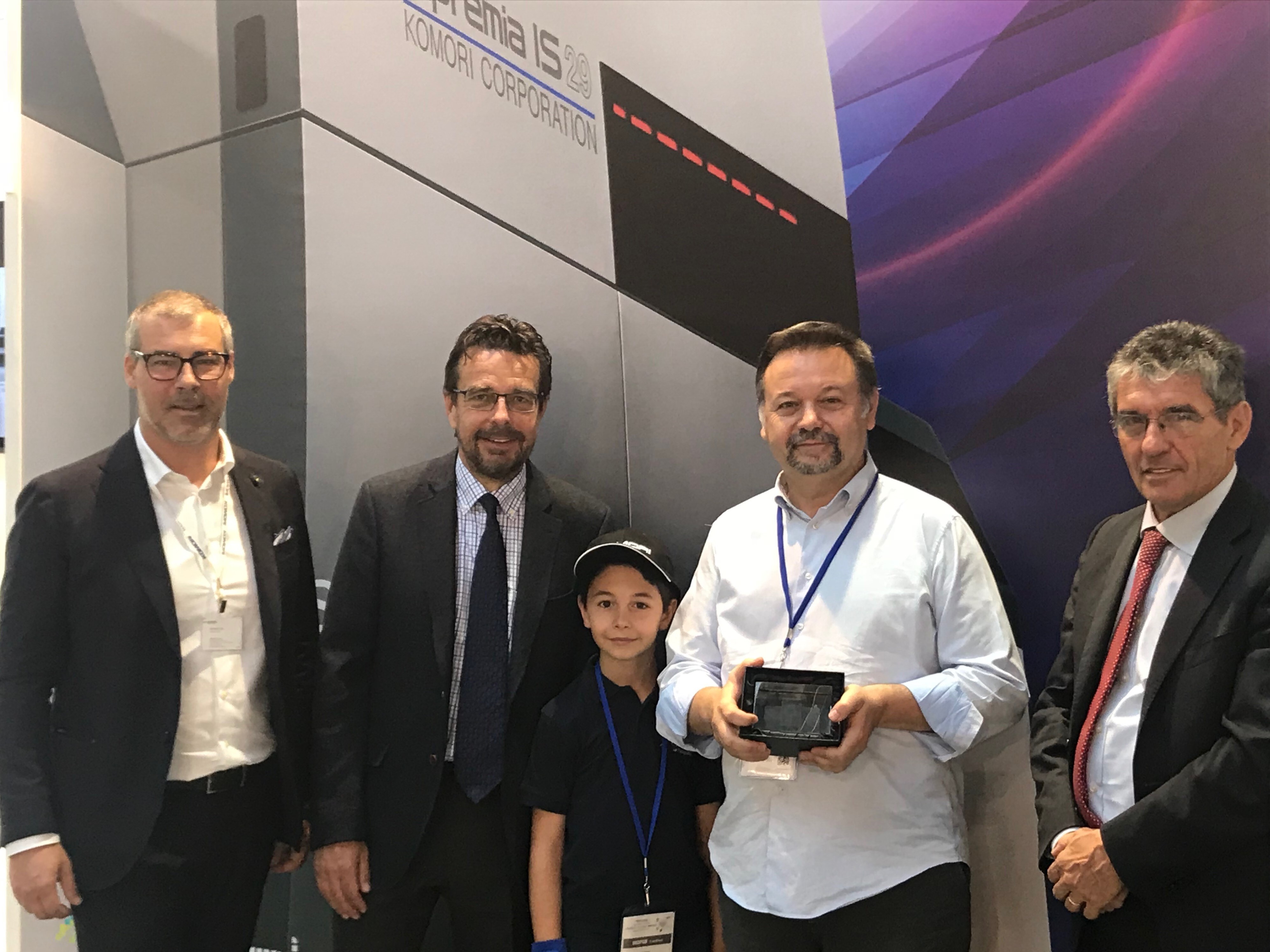

Pictured during Print4All in Milan, from left to right: Giampaolo Zani (Digital Sales Manager for Komori Italy) - Komori Europe's Chief Operating Officer

Neil Sutton - Vittorio Ferrone and Vito Forreno for Loretoprint and Silvano Bianchi, Managing Director for Komori Italy.